Mineral bentonite purification method can be divided into three types, namely, dry and wet hand selected winnowing water. The hand selection is mainly used for high montmorillonite content of bentonite ore. Hand selected general in the mining field, artificial pick out the waste rock in the ore. Can also be based on the application of technical indicators in the area of the location of the lot, the layer of mining, respectively, stacked, separate processing. At present, the domestic multi choice, processing flow is as follows:

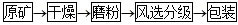

Firstly, the bulk of bentonite ore is crushed to 20 mm or so, soft bentonite without broken, then dry ore, make water down to 6 ~ 12% below. Can be heated to dry, can also be naturally dry. The third step is to hand selected, in the dry process with artificial pick out more than 20 mm of waste rock, some mines with vibration sieve sieve out more than 20 mm of bulk. The fourth step of grinding, usually by Raymond mill, product fineness is generally 200. Air purification method is used widely at home and abroad. The content of the general inclusion grade should be more than 80%. The principle of flow winnowing are as follows:

Drying generally second paragraph, put ore in material field of natural drying, ore moisture was reduced from 40% to 25% the following, and then coarse crushing, crushing product grain size of 30 to 40 mm. Further drying of the broken products, the general use of air drying and fluidized drying. The drying device mainly fluidized dryer, rotary shutter type dryer, cyclone dryer, rotary dryer etc..

Drying temperature 250 degrees C below, the product moisture control in less than 6 ~ 12%. The drying temperature is too high or too long drying time will affect the quality of products, and even lose colloidality. The general milling Raymond mill, product fineness and according to user requirements, generally 100 to 325. After grinding products with a cyclone type classifier classification desand (Miscellaneous) after the final product is obtained. In order to obtain high purity bentonite or montmorillonite, and to process and utilize the low grade bentonite resources of 80% ~ 30, the wet or wet purification process is adopted.

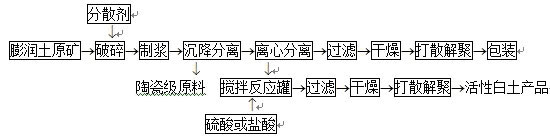

The wet purification process of bentonite is shown in Figure 1. The bentonite raw ore broken to less than 5 mm, add water, stir into the concentration for about 25% of the pulp and spiral classification level or other hydraulic classifier isolated coarse sand and carbonate minerals. The remaining suspension into the high-speed rotation of the centrifugal settling separator, such as horizontal spiral unloading settling centrifuge, separating a fine-grained carbonate and feldspar and other impurities.

Particle size less than 5mm, the expansion ratio of more than 20 high purity montmorillonite or swelling bentonite slurry or suspension, the slurry filtration, drying and scattered depolymerization to obtain high-purity bentonite products. After centrifugation deposition in addition to a small part of the fine-grained carbonate and feldspar and other impurities also contains a lot of can meet the requirements of the production of activated white clay bentonite. Therefore, the the with a certain amount of acid reaction can production of activated white clay.

Process flow chart of wet purification of Bentonite

Another wet purification method is the heavy partial phosphate method. The law is the bentonite slurry added to contain industrial six partial sodium phosphate dilute solution, the impurity minerals precipitated rapidly and then separate them. Concrete process is as follows: firstly, the pulp made from bentonite, liquid to solid ratio is 1.5 ~ 2, and then the pulp into the metering mixing, while adding sodium hexametaphosphate solution, dosage is about 0.5% by weight of bentonite.

For the rapid settlement of bentonite, the concentration of sodium phosphate solution should not be too thick. Mixed slurry into precipitation precipitator, grit is impurities, further separation of the suspended solids, purification, drying, depolymerization, you can get high-purity bentonite. Repeated precipitation can be repeated, and the content of montmorillonite can be obtained more than 99%. Source: China Powder Technology Network