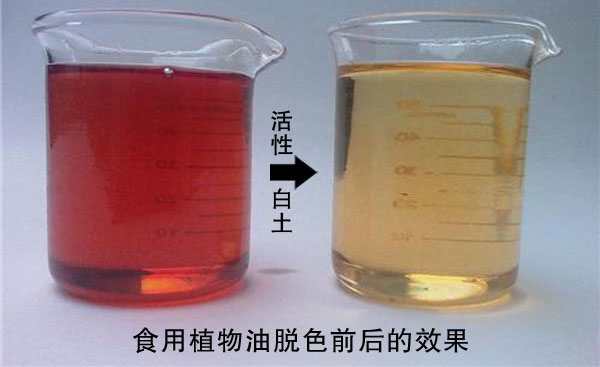

Soybean oil in refining pressing process must be after removal of acid dehydration and decolorization processing before they can reach the standard of clear, pure, safe, currently used in the decolorization process of soybean oil decolorization adsorption agentAtlapulgite。

After more than using activated clay of soybean oil production factory found that the decolorization process of physical vacuum adsorption decolorization effect is the best. In this process of activated clay added amount in 3-5% between, bleaching temperature control in about 90 DEG C, bleaching time should be not less than 30 minutes is appropriate.

Because of the climate and other reasons can sometimes lead to soybean in immature before harvest, so called soy beans. Because the green beans contain chlorophyll, squeeze the oil color and mature soybeans vary, which will be green, then using activated clay is difficult to achieve an ideal decolorization effect.

After testing, in to the bleaching of chlorophyll containing soybean oil can be just the right amount of addition of activated carbon, activated carbon and activated clay ratio 1:10 If chlorophyll bleaching effect is still not ideal, can be an appropriate increase in activated carbon addition proportion.